Architectural Metalwork, Without the Headaches

We’ll take it from here ….. Whether you’re working from a napkin sketch, a placeholder detail, or a simple floor-to-floor dimension, we develop professional, architectural-grade shop drawings and highly realistic renderings that drop directly into your construction set—and help you communicate intent, secure approvals, and sell the vision to your client.

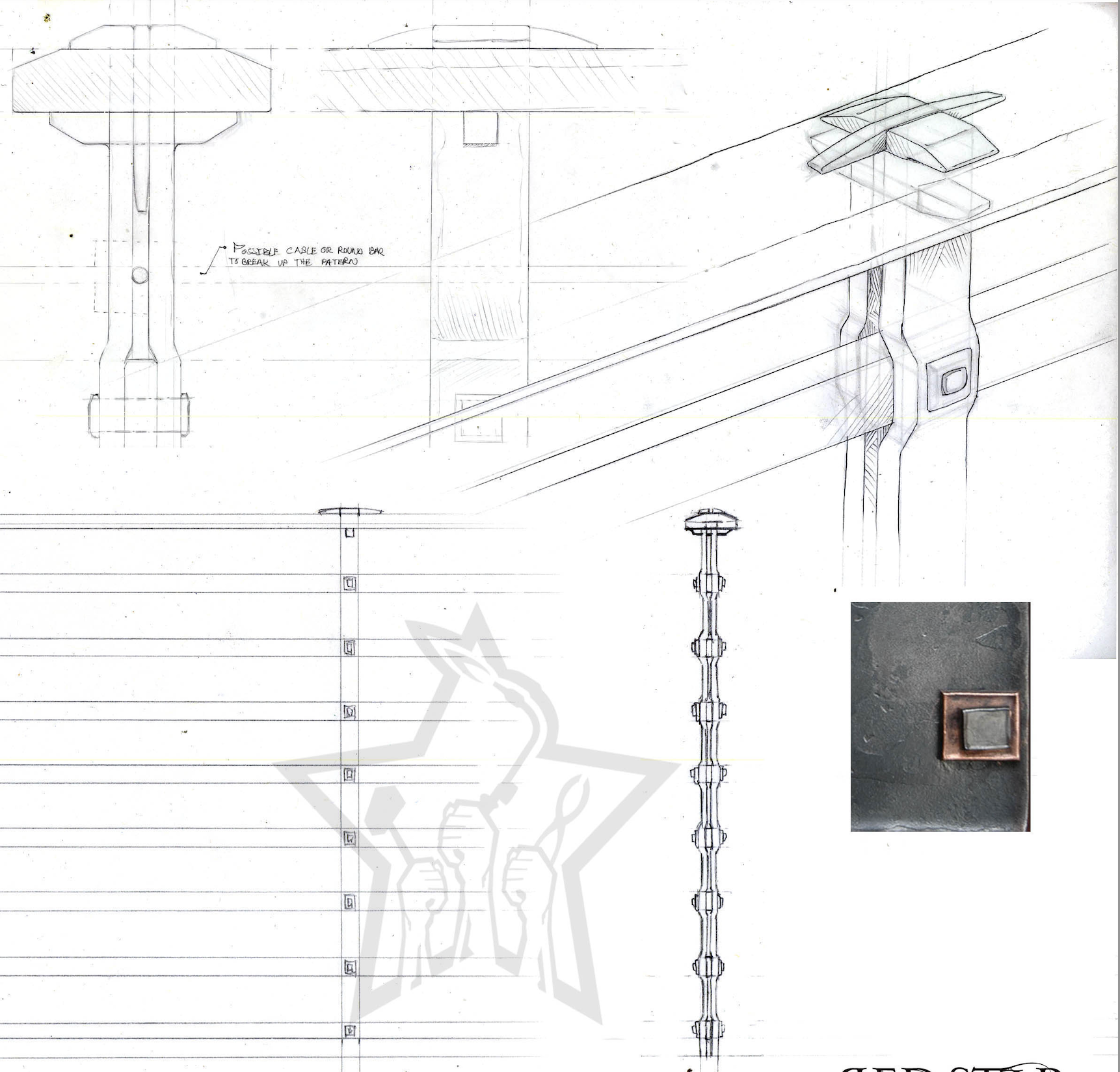

RSI Archive Project Sketch

We Were Artists First

Before Red Star Ironworks was a fabrication shop, it was a drawing table. Long before CNC files and 3D models, our work began with blue pencils, ink pens, and vellum—working through proportions by hand, chasing light and shadow, and figuring out how an idea should feel before worrying about how it would be built. Turning drawings into physical objects wasn’t a process we learned later—it was the foundation.

That mindset still defines how we work. Give us a napkin sketch, a hand drawing, or a half-formed idea, and we know how to translate it into metal because that’s how we started. We learned by making—by cutting, welding, grinding, and refining until the piece matched the intent of the drawing. The tools have evolved, but the instinct hasn’t. Every project still begins with the same question: What is this supposed to be, and how should it live in the space?

Today, we use sophisticated software, digital modeling, and precision fabrication tools—but they’re just extensions of that original way of thinking. The artistry comes first. The technology serves the idea, not the other way around. That’s why our work reads clearly on paper, in renderings, and in the finished build—and why builders, architects, and designers trust us to take an idea and carry it all the way through, without losing its soul along the way.

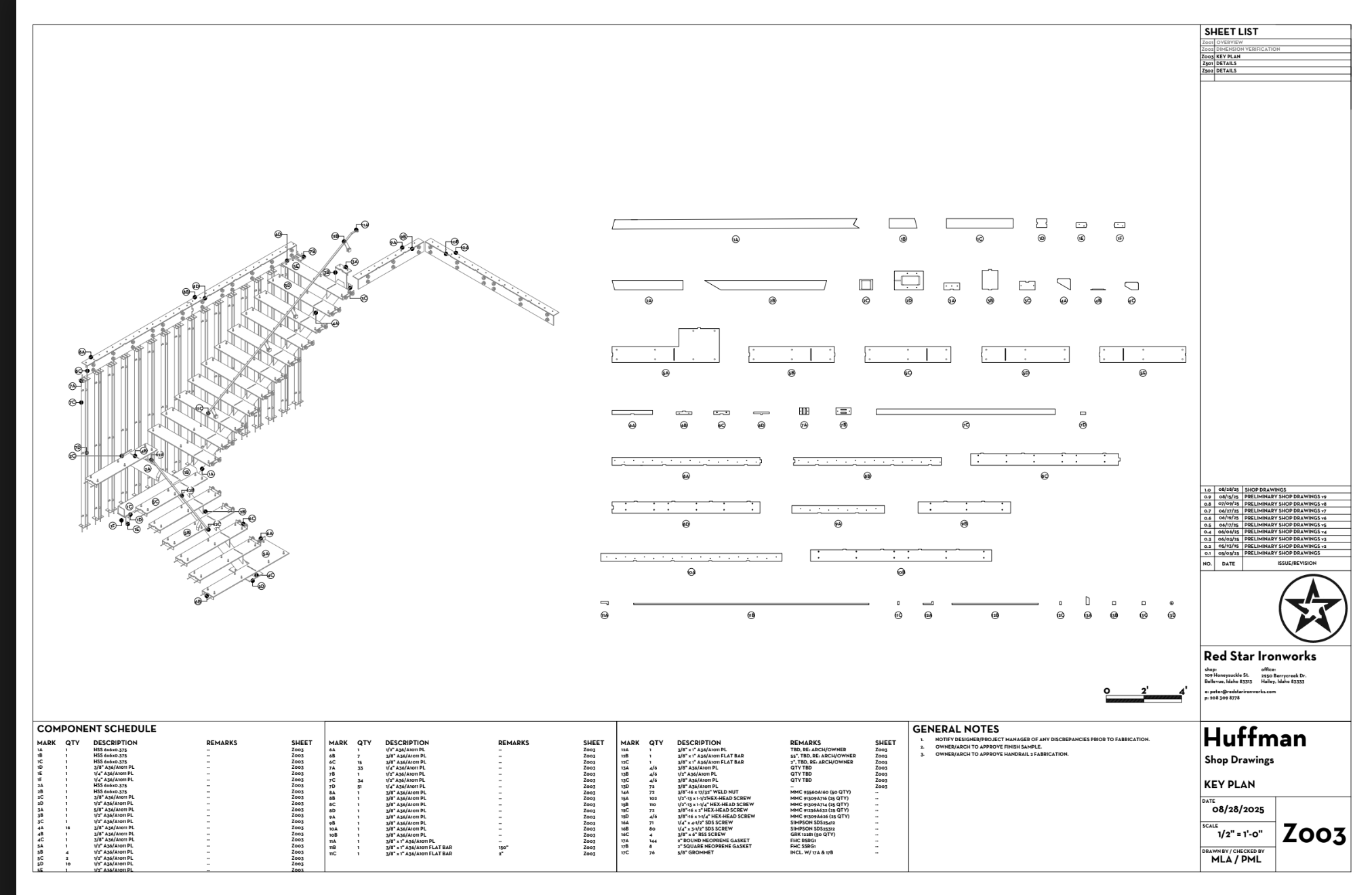

Floating Stair in Whitecloud

Great metalwork lives or dies on the drawings.

That’s why we treat shop drawings as a critical coordination tool—not a formality. Our process begins in the field, where we use precision measuring and 3D scanning to capture real-world conditions as they actually exist, not as they’re assumed to be. Walls aren’t perfectly plumb, floors aren’t perfectly level, and structures rarely land exactly where drawings suggest. We account for that early, so it doesn’t become a problem later.

From there, we develop fully resolved, architectural-grade shop drawings that communicate clearly to everyone involved. Hardware locations, mounting methods, substrates, tolerances, and adjacencies are called out explicitly. Existing conditions are documented, transitions are thought through, and installation sequencing is considered before material is ever cut. The goal is simple: no surprises in the field, no guessing on site, and no ambiguity during review.

To do this, we work fluently across multiple professional design and engineering platforms—AutoCAD, Vectorworks, Rhino, Fusion 360, and SolidWorks—selecting the right tool for the job rather than forcing every project into a single workflow. This allows us to model complex geometry, resolve connection details, and deliver drawings that integrate cleanly into architectural and construction sets. The result is shop drawings that builders and architects can trust—accurate, legible, and built for execution, not just approval.

Custom Stainless Steel Grill Station

There’s a moment in every project when things either click—or stall.

For many clients, that moment comes when they can finally see what’s being proposed. That’s where lifelike renderings become more than a presentation tool; they become a decision-making tool. Using state-of-the-art software and proprietary workflows developed in-house, we create renderings that place architectural metal into the space as if it already exists—accurate in scale, proportion, material, and light.

These aren’t abstract visuals or loose concept images. Our renderings are built from the same geometry and information that drives our shop drawings and fabrication. Materials behave the way they actually will. Finishes read honestly. Sightlines, shadows, and adjacencies are intentional. The result is a clear, realistic preview of how the metalwork will live in the architecture—how it feels from across the room and how it reads up close.

In fast-paced architectural and construction environments, that clarity matters. Instead of asking clients to interpret intent from black lines on a flat page, renderings allow everyone—builders, architects, designers, and owners—to align quickly and confidently. Questions get answered early. Decisions happen faster. Revisions are intentional, not reactive. Most importantly, clients gain the comfort of knowing exactly what they’re investing in before steel is cut. It turns uncertainty into confidence—and keeps projects moving forward with momentum instead of hesitation.